- Plot No 6/4, Road No 11, IDA Nacharam, Hyderabad, Telangana - 500076, India.

SREENEX COLLOID MILL

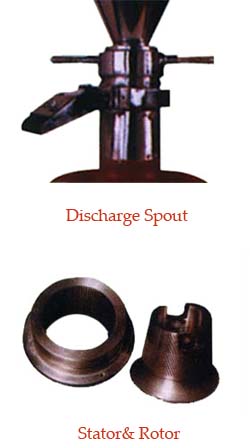

SREENEX Colloid Mill gives high shear and centrifugal force generated between the rotor and stator are exerted on the product. The toothed profile of the rotor and stator, combined with a high flow rate, generate additional gravitational force to give through and even processing. Is an Ideal machine for homogenising, emulsifying, grinding, dispersing, mixing, extracting, etc.

The toothed rotor-stator system used in SREENEX colloid mill guarantees the micro crushing of a wide variety or raw materials with the product being simultaneously dispersed and homogenized.

The mill offers a micro-distribution of 5 to 10 microns. The robust design and assured quality of the SREENEX colloid mill guarantee a long service life with minimum maintenance.

Techinical Specification

| Model | SCM-5 | SCM-7.5 |

|---|---|---|

| Output* | 100 to 1500 Ltrs/Hour | 150 to 2500 Ltrs/Hour |

| Particle Size Reduction* | 5 to 10 Micron | 5 to 10 Micron |

| Hopper Capacity | 15 Ltrs | 26 Ltrs |

| Electrical Motor | 5 HP/3.7 Kw/3000 RPM/415 V/50 Hz/3 Phase | 7.5 HP/5.5 Kw/3000 RPM/415 V50 Hz/3 Phase |

| Floor space in mm / Direct Drive Belt Drive | 800 (L) X 500(B) X 1250 (L) X 500(B) X 1250(H) | 900(L) X 550(B) X 1350 (L) X 500(B) X 1400(H) |

| Case dimension in mm / Direct Drive Belt Drive | 650 (L) X 650(B) X 1300(H) 1450 (L) X 700(B) X 1400(H) | 700 (L) X 700(B) X 1400(H) 1550 (L) X 700(B) X 1500(H) |

| Net weight in Kgs / Direct Drive Belt Drive | 225 (approx) / 250 (approx) | 180 (approx) / 200 (approx) |

| Gross Weight in Kgs. / Direct Drive Belt Drive | 250 (approx) / 275 (approx) | 300 (approx) / 360 (approx) |

Application

Pharmaceutical, Food, Dairy, Confectionery, Cosmetics, Chemicals, Textile, Ink, Ceramics, Detergent, Rubber and other industries.

Optional

- Water jacketed model

- S.S 316 in place of S.S.304 contact parts

- Flameproof electrical fittings

- Compact and easily cleanable

- GMP model in place of standard model

- Discharge spout for viscous products

Salient Features

- All contact parts are made out of 304 stainless steel

- Coupling provided between motor shaft & Rotor shaft for easy maintenance

- High outputs

- Simple in construction

- Versatile in use

- Easy to clean

- Maximum adjustment for minimizing milling gap

- Consistency in performance

- Oil seal & motor protection cover are provided

- Leak proof neoprene sealing provided to avoid leakages